Tool developement

Manufacturability analyses and tool development at WAFIOS Umformtechnik

Our name has stood for high-quality cold forming for over 100 years.

But we are also at your side as a partner and support you in tool development and feasibility studies. We are happy to share our knowledge and the know-how with you that we have gained through decades of experience.

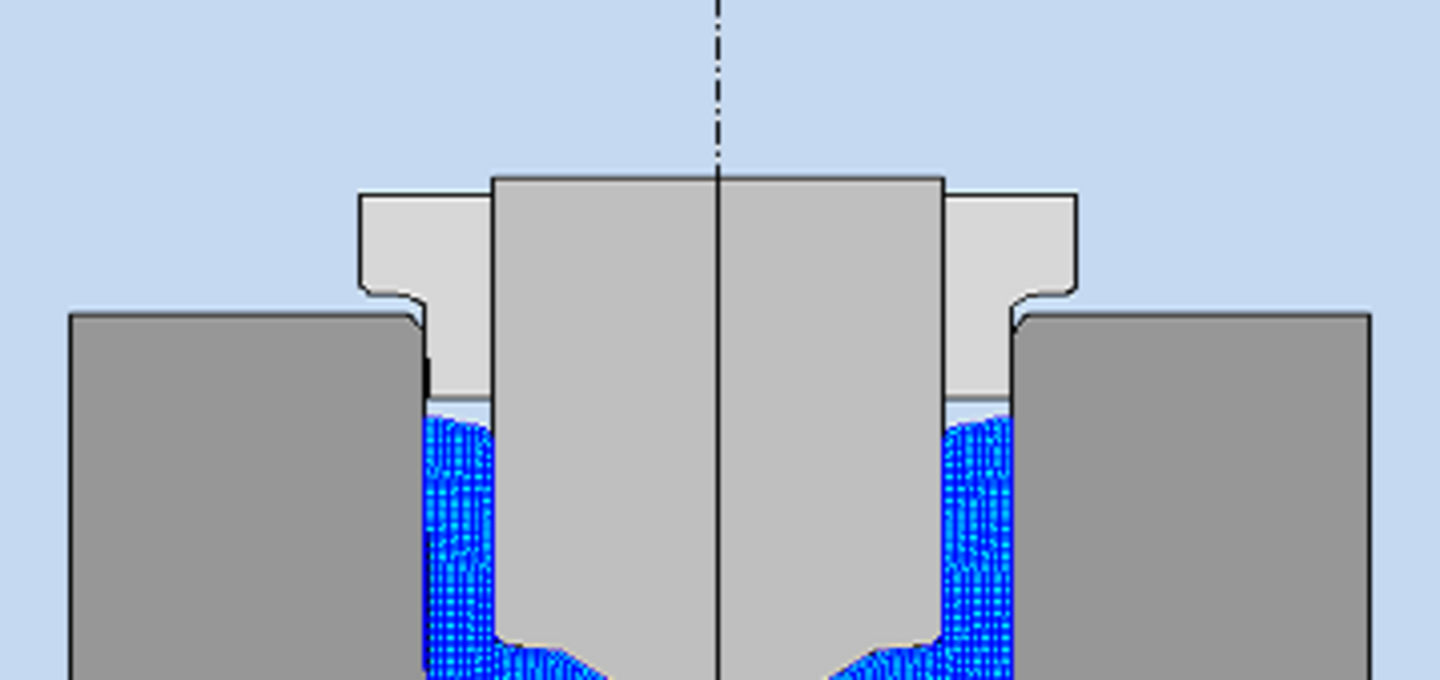

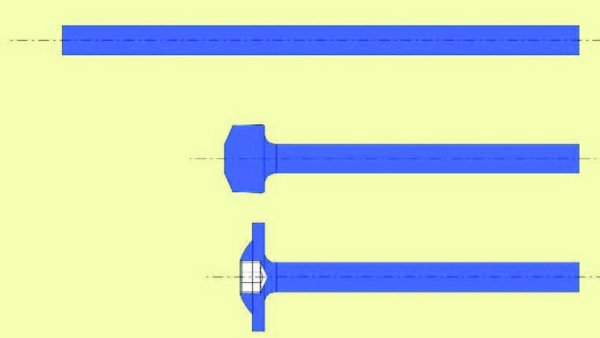

CACH DB

With this system we can present the stages in a simplified way.

Volume, compression, reduction and cup ratios as well as the approximate pressing force can also be calculated.

This is particularly helpful for the rough selection of potential machines.

We also simulate the transport and feeding of the pressed parts in order to determine the ideal gripper dimensions.

The tools are drawn in a simplified way for this purpose.

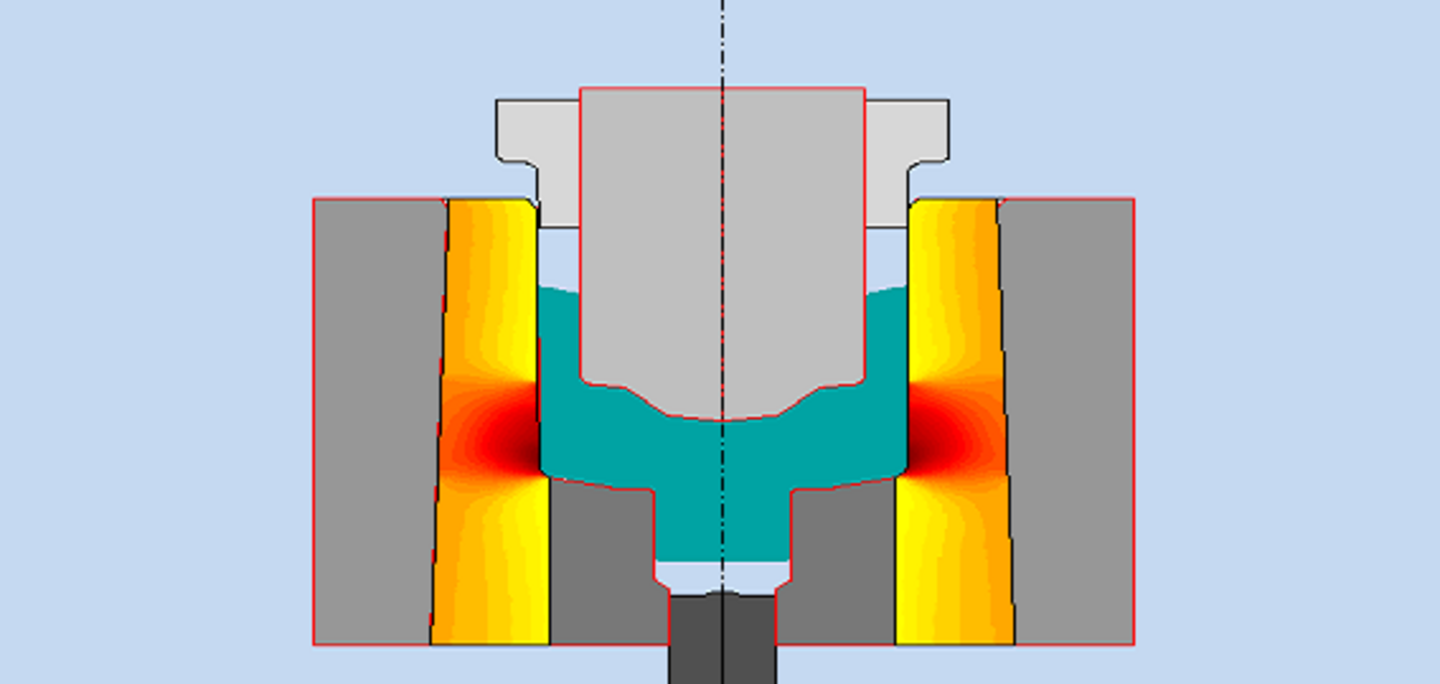

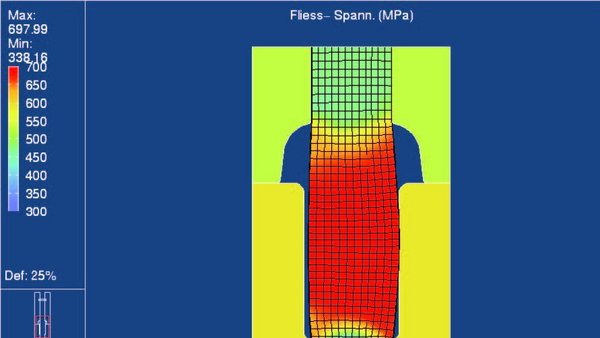

eesy-form 2D

With eesy-form we analyze your material flow precisely in order to detect any wrinkles or other errors at an early stage.

This makes sense especially for complex products and should always be carried out in advance.

At the same time we analyze the different tensions and forces - both on the product and on the tool.

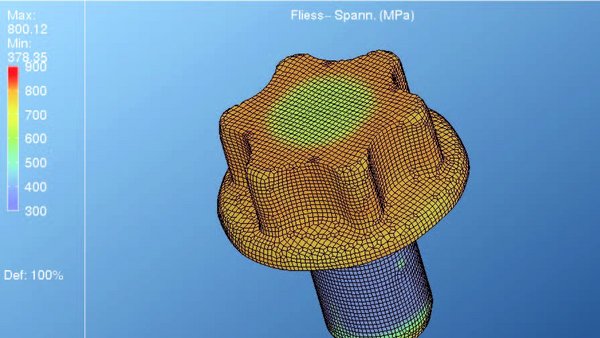

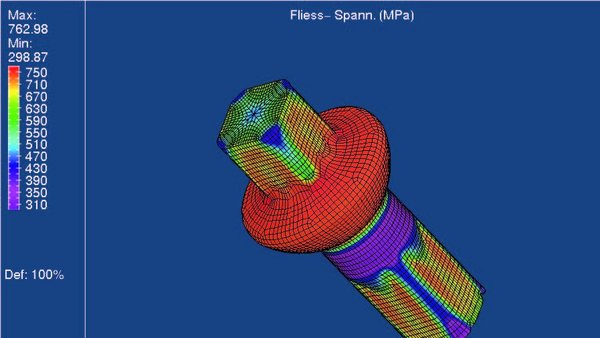

eesy-form 3D

With this system we can create even the most unusual contours and geometries for you.

Using a 360° simulation we can also detect buckling in the material if the compression ratio is too high or the tool is not ideally designed.

We are well equipped and networked to support and assist you – whether for our own machines or those of other manufacturers.

If you wish, we can supply you with the finished construction and accompany the commissioning in your company.