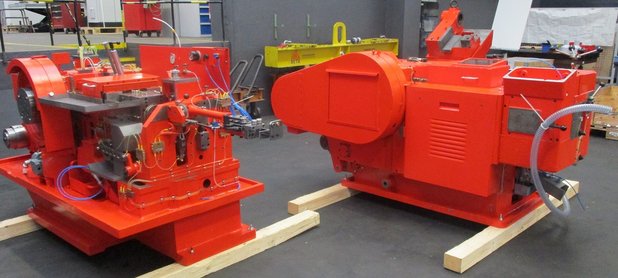

Machine overhauls by the manufacturer

Bring your WAFIOS machine up to date with the latest technology and ensure the availability of your systems with sustainable measures. Avoid unforeseeable failures during your production peaks or a total failure due to discontinued spare parts.

With our extensive retrofit solutions, we give your old machine a new future. Rely on our retrofit concepts and benefit from the availability of spare parts, a new warranty and a process-reliable machine.

Upgrades for a future-proof factory:

Thanks to our extensive experience, you can benefit from new technical developments that are of considerable benefit to the availability, productivity and process quality of your system.

Our tried-and-tested overhaul concepts offer you a decisive competitive advantage.

In order to keep your production downtime to a minimum, we also offer you overhauled machines in exchange for your old machine.

Your path to sustainable production:

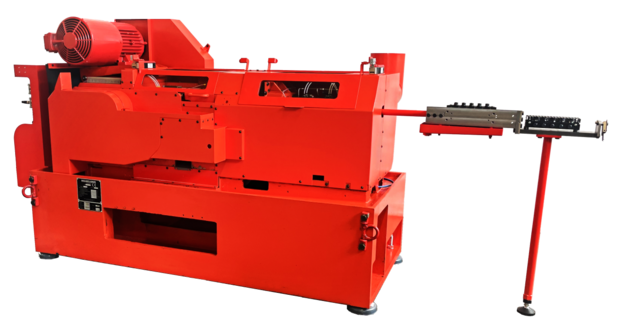

We offer you individual retrofits/general overhauls according to your wishes and requirements.

The mechanical and electrical systems are renewed to the latest state of the art, as is the retrofitting of CE-compliant safety devices.

The advantages are obvious: Due to the continued use of existing tools and the know-how of the machine operators, more and more customers are preferring retrofits to a new system.

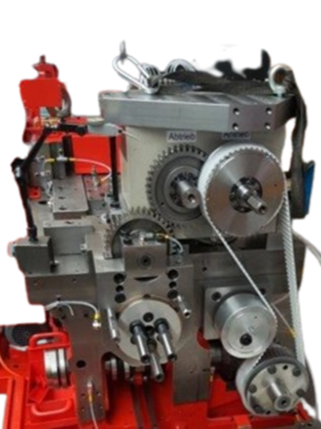

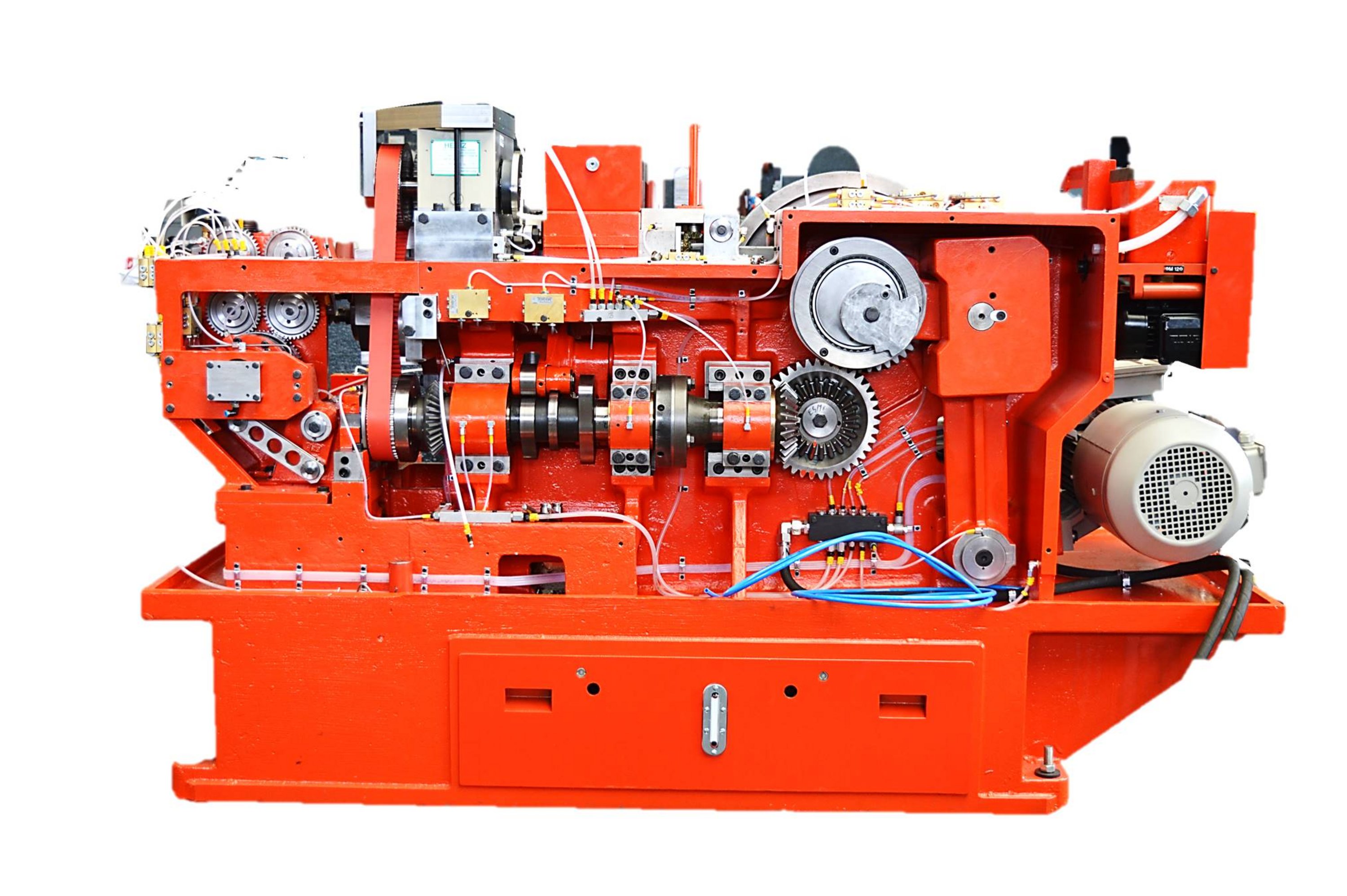

Example: Upgrade stepping gear HC5

Among other things, by reducing the number of parts from around 25 to 15 in the rotor drive area and from around 20 to 7 in the rotor locking area, we were able to reduce long-term maintenance costs many times over.

This conversion, which is now installed as standard in HC5 retrofits, paves the way for a future-proof production facility that will be reliably available to our customers for decades to come.